Today was a first on several counts:

1. Brewed 2 beers in a day

3. Reusing yeast by innoculating a Witbier with some yeast I washed a few weeks ago.

4. Stayed (mostly) sober throughout brewday - somewhat of a feat for many of us home-brewers.

Oh yeah, and 5. FINALLY doing a write up of a brewday walk-through. Whoop!

Anyway, we started about 10am after coming back from Houston this morning. First batch was Armadillo Amber, a sessionable Amber Ale I've been meaning to brew since January. Second batch was a Witbier I've named Wit Girl Wasted. Cheesy name, yes, but it's a tribute of sorts to Angela. She got me started in the hobby about 1.5 years ago and this was my way of giving thanks to her for being so supportive of my passion (she digs those Belgian beers).

But enough with the sappy stuff; here's the walk through:

|

| Getting mash infusion to temp. |

|

| Checking mash temp to make sure we're good to go. |

|

| Mashing AA (no pun intended). |

|

| After vorlaufing, transferring first runnings to keggle. |

|

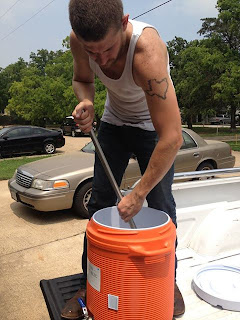

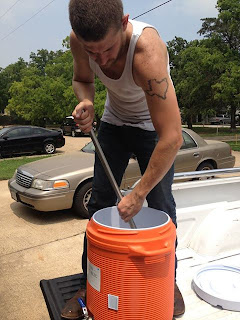

| Blake earning his keep - stirring in 1st sparge. |

|

| Overhead view of transfer. |

|

| Transfer complete, time to start the boil. |

|

| Ready to start boil. |

|

| Boiling away! |

|

| Getting the immersion chiller in position. |

|

| Boil done. Sanitizing the valve for transfer to primary. |

|

| Starting transfer to primary fermenter. |

|

| Transferred to primary, yeast added, capped and ready to ferment! |

The entire process usually takes about 4 hours, but by efficiently stacking steps we knocked out two brews in about 6.5 hours, including cleanup time. Not too shabby, IMO.

Here's what's happening now - Two very happy batches inoculated with their proper yeasts and finally actually CREATING beer.

|

| A full fermenter is a happy fermenter. |

All in all it was a long but productive, and ultimately rewarding, brewday. In a few short weeks we'll be bottling these beauts. After carbing for couple more weeks they'll be ready to drink.

Armadillo Amber (Amber Ale) and Wit Girl Wasted (Belgian Witbier) will clock in at about 5.2% and 4.2%, respectively. Everything went smoothly (for once, hah) and I got to show a fellow enthusiast and good friend the basics of AG brewing. Prost!